Wastewater and Reuse

Wastewater and Reuse Technologies for Your Site

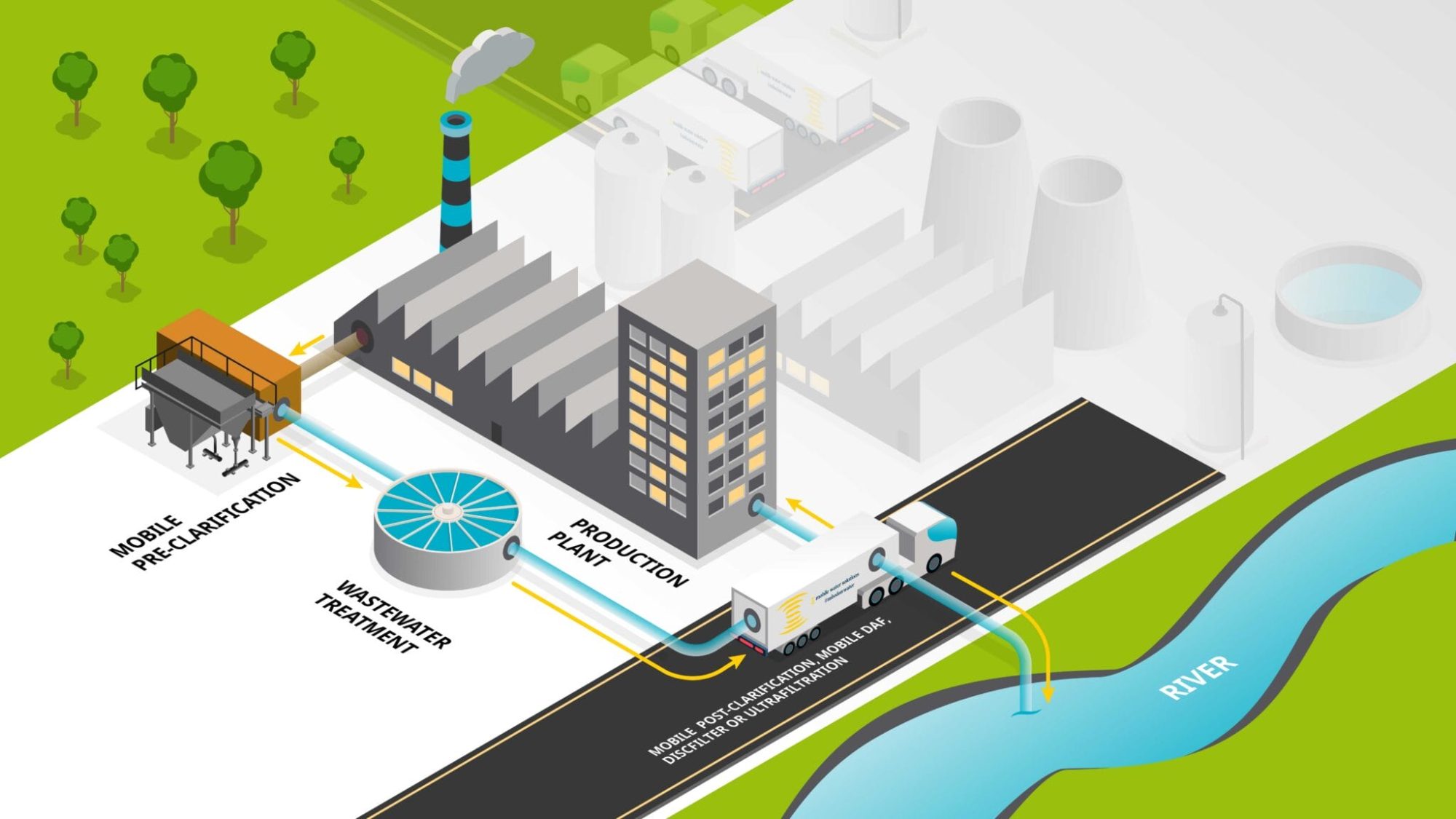

Efficient industrial wastewater treatment is pivotal in returning wastewater to its source. However, industrial processes often generate effluents that pose challenges due to their varying volume and composition. In response, plant operators are increasingly seeking ways to enhance the reliability and efficiency of wastewater treatment at their industrial sites.

Mobile Water Solutions can help industrial sites protect their license to operate and reduce their environmental impact when faced with issues and a rapid response is needed. A broad range of physical and chemical technologies is available for industrial wastewater applications, including disc filters, multi-media, activated carbon filtration, sand-ballasted clarification and air flotation with preliminary coagulation and flocculation, and recycling (UF/RO systems).

Discover how to guaranteed your wastewater treatment continuity

Download

Curious about temporary water or wastewater treatment services?

TALK TO AN EXPERT

Unlocking the power of mobile wastewater treatment solutions

-

Fast-track “plug-and-play” modular solutions

Pre-engineered for ease of use and space optimization, with modularity for added functionality or throughput

-

Flexible “pay-as-you-go” agreements from days to years

-

Ensured compliance with local discharge standards

-

Water footprint optimization

Reduced dependence on limited freshwater resources through effective reuse solutions

-

A flexible solution for your most pressing needs

Covers the period of equipment servicing and helps address temporary variations in effluent quality

Your partner in sustainable wastewater and reuse practices

Mobile Water Solutions partners with diverse industries and utility companies, offering robust wastewater treatment and reuse solutions.

Discover some of our standout references and learn how our clients have ensured uninterrupted wastewater treatment operations through the utilization of temporary mobile solutions.

More Technologies

Discover our wastewater and reuse solutions

Mobile Water Solutions offers an array of cutting-edge process water technologies customized to fulfil the unique demands of diverse industries. Whether you’re seeking the ideal technology to treat feedwater, minimize chemical usage, enhance plant efficiency, or address various other needs, we have you fully covered.