Petrochemical

Mobile Water and Wastewater Treatment Solutions for the Petrochemical Industry

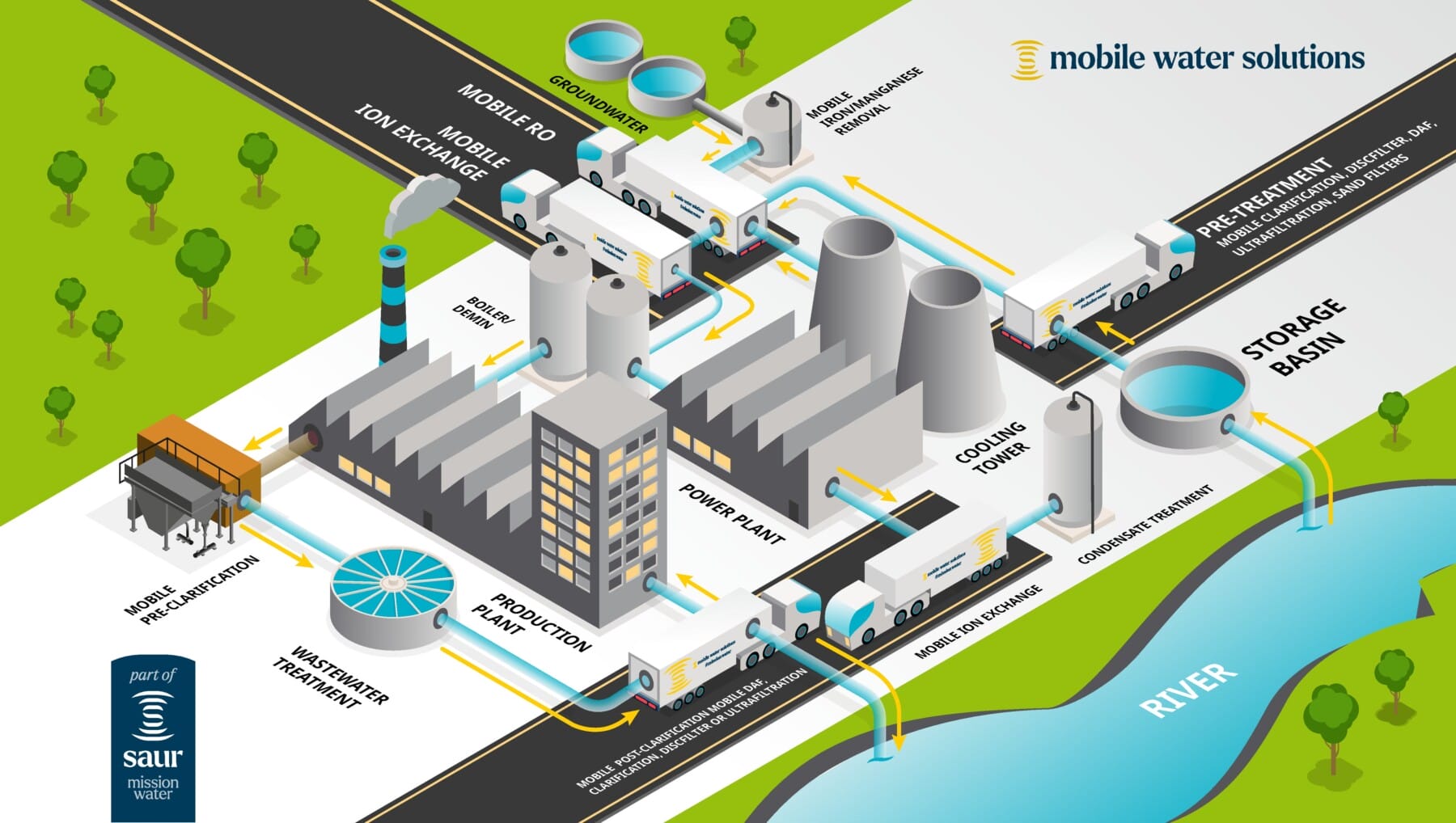

Temporary mobile water and wastewater treatment services provide an optimal solution for diverse process stages within petrochemical plants. They reduce fixed costs and ensure 24/7, 365-day uninterrupted supply.

As industrial operators increasingly prioritise enhanced water management, optimising treatment processes becomes paramount for maintaining competitiveness in the petrochemical sector.

Crucial Water Dynamics in Petrochemical Operations

Water management is crucial in the petrochemical industry, where flow rates and treated water quality directly impact production efficiency and environmental compliance. Water serves as a critical resource across petrochemical plants, utilised for cooling, steam generation, cleaning, and washing. Optimising water usage and ensuring effective wastewater treatment are critical for sustainable and responsible operations in petrochemical industries.

Varied Flow Rates and Quality Demands

Flow rates vary widely, ranging from hundreds to thousands of cubic metres per hour (m³/h), and water quality requirements show diversity based on specific applications. Precise purity is essential for water used in chemical reactions and heat exchange to prevent undesired interactions and maintain reaction efficiency. This emphasises water’s significance in averting issues like fouling, scaling, and corrosion, ensuring optimal heat transfer efficiency. Effective wastewater treatment in the pharmaceutical industry facilitates efficient resource management and compliance with environmental regulations.

Advantages of Mobile Water Solutions in the Petrochemical Industry

Opting to replace or supplement fixed water or wastewater treatment systems with temporary mobile solutions offers transformative benefits to the petrochemical industry. Some of these benefits include:

- Operational Agility: Quickly adapt to fluctuating production needs and respond effectively to emergencies.

- Continuous Water Treatment: Ensure uninterrupted water treatment for consistent operations.

- Economic Efficiency: Reduce fixed costs and optimise water management budgets.

- Environmental Responsibility: Minimise environmental impact and comply with regulations.

- Flexibility: Respond to changing demands and maintain operational continuity.

- Success in a Dynamic Sector: Gain a competitive advantage with adaptable and sustainable water solutions.

Secure your energy production continuity. Anytime, anywhere.

Download

Petrochemical Applications

Mobile Process and Boiler Feed Water

Mobile Process and Boiler Feed Water

In petrochemical processes like cooling, steam generation, and chemical reactions, effective water treatment methods are crucial. These methods, such as Reverse Osmosis, Ion Exchange, Filtration, Clarification, and Desalination ensure water quality, equipment protection, and environmental compliance. They enable the petrochemical industry to meet standards, minimize impact, and maintain efficiency.

- Boiler make-up water for steam generation

- Process water

- Condensate polishing

- Post or pre-treatment of your existing plant

- Additional treated water for commissioning or projects

- Temporary service for refurbishment or maintenance

- Failure of water treatment plant

- Severe weather conditions

- Cooling water treatment

Mobile Wastewater and Reuse

Mobile Wastewater and Reuse

Wastewater treatment is crucial for managing and treating effluents. Various processes like Primary, Secondary (Biological), and Tertiary Treatment are used. Technologies like Flotation, Reverse Osmosis, Membrane Filtration, and Sludge Dewatering are also applied. These processes and technologies ensure proper effluent disposal, minimize environmental impact, and meet regulations.

- Emergency response

- Pre-treatment

- Biological treatment

- Adaptable capacity

- Painting and coating operations

- Seasonal operations

- Construction and expansion

- Dewatering sludge

- Micro-pollution

- pH adjustment

- Regulatory compliance

- Shutdown and turnaround

- Water reuse

- PFAS removal

Discover the best solutions for your industrial applications

Talk to an expert